close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

VFF-200

Valuen

Working Principle;

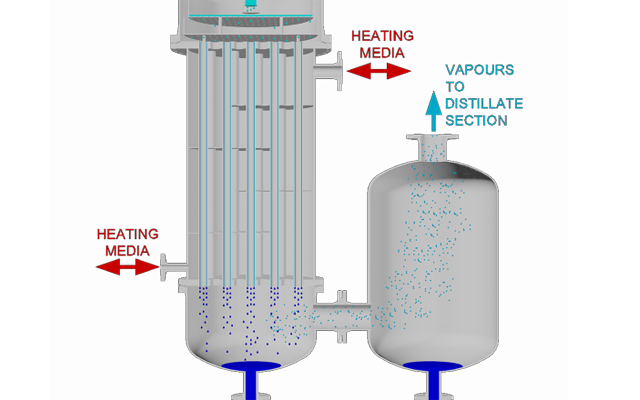

Falling film evaporation is to feed solution from the upper tube box of the heating chamber of the falling film evaporator, and distribute it evenly into each heat exchange tube through the liquid distribution and film forming device. Under the action of gravity and vacuum induction and airflow, the solution flows into a uniform film from top to bottom in the heating chamber. During the solution flowing, it is heated and vaporized by the heating medium on the shell side, and the generated steam and the liquid phase enter the separation chamber together. After the vapor and liquid are fully separated, the steam enters the condenser for condensation( or enters the next evaporator as the heating medium to achieve multi-effect operation), and the liquid phase is discharged from the separation chamber.

| Model | VFF50 | VFF100 | VFF200 |

| Evaporation Rate(L/H ) | 50 | 100 | 200 |

| Solvent Tank Volume(L) | 50 | 50 | 100 |

| Heating Area (㎡) | 3.1 | 5.2 | 10.3 |

| Condensation Area(㎡) | 3.2 | 9.8 | 19.4 |

| Discharge Pump(t/h) | 1 | 3 | 3 |

| Pumping Rate of Vacuum Pump (m³/h) | 18 | 40 | 100 |

| Power Supply | 220V or 380V or 480V, 50/60HZ, 3 Phase | ||

| Material | Sanitary Grade Stainless Steel 304 or 316L | ||

| Ancillary Equipment (Optional) | Heating Circulator or Steam heater, Water cooling chiller (or water cooling tower) | ||