close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

VTF-150

Valuen

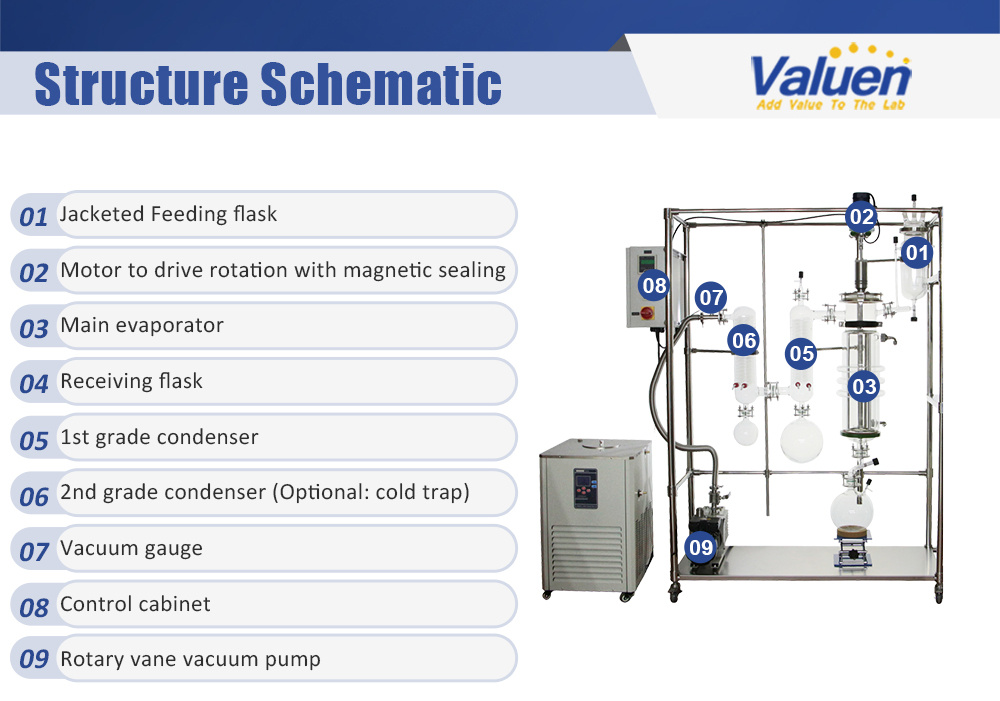

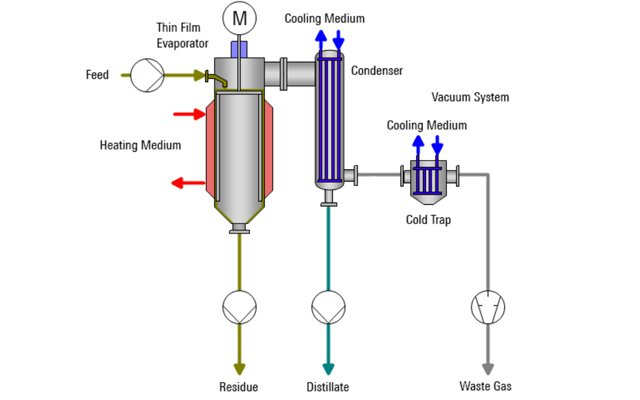

The thin film evaporator consists primarily of a heating jacket,an internally rotatable wiper, and a condenser and vacuum system. In the high vacuum system, the feeding liquid is fed from the upper part of the evaporator. After that, under the driving of the gravity and the rotating wiper, a downwardly swirling film is formed along the inner wall surface of the jacket.The finishing fluid is discharged from the bottom discharger,while the steam is discharged from the upper part. The system is very suitable for liquid materials with high viscosity, easy crystallization, easy scaling, suspended solids or heat sensitive properties, and is widely used for pretreatment and finishing of products in the chemical, pharmaceutical, health care and other industries.

| Model | VTF-60 | VTF-80 | VTF-100 | VTF-150 | VTF-200 |

| Feeding rate(L/h) | 0.5-5 | 1-7 | 2-10 | 3-15 | 5-20 |

| Evaporation area(m²) | 0.06 | 0.1 | 0.15 | 0.25 | 0.35 |

| Condenser area(m²) | 0.05 | 0.25 | 0.3 | 0.34 | 0.6 |

| Feeding tank volume(L) | 1 | 1 | 2 | 2 | 5 |

| Material | Wetted Parts: High borosilated glass; Rack and Other Parts: Sanitary Grade Stainless Steel 304 | ||||

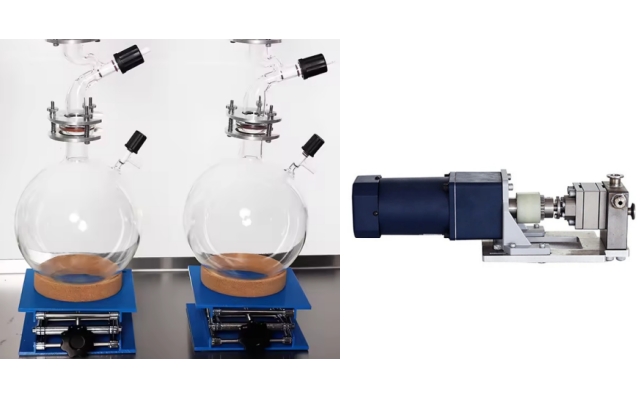

| Cold Trap & Condensers | 2 Modules for Options: I: 1 Cold Trap with Coils Inside; II: 1 Coils Condenser and 1 Cold Trap with Coils Inside | ||||

| Minimum operating pressure(mbar) | ≤0.01 mbar | ||||

| Working temperature range(℃) | Room temperature to 300 °C | ||||

| Utilities (Optional) | Heaters for Feeding Flask, Main Evaporator; Chillers for External Coils Condensers Vacuum Pump ( 1 or 2 stage) | ||||

| Power supply | 220V,50/60Hz; 380V,50/60Hz (Other voltages available) | ||||